Category: Woodworking

Logging in the winter

I brought my GoPro with me when logging and riding my snowmobile.

Milling with my sawmill

Sawmill unboxing

Bed legs

We got new beds and instead of spending 1600 kr to buy 8 blocks of wood with a screw in them I decided to build my own bed legs.

For material I choose to use some 75 mm birch slab that I sawed out of a blowdown tree a few years ago. I had to work around knots and damages but ripped and milled it down to 60×60 mm stock.

After crosscutting the blanks to 200 mm length I marked the center in one end of each piece. At the mark I drilled a 6 mm hole for a m8 stud screw.

Then I cut the taper of each leg at the table saw using a jig that I made the last time I built bed legs but any tapering jig can be used. The first two sides of the leg is easy but the next two sides has to be compensated with a wedge.

To remove cut marks from the saw I used a hand plane before rounding off the corners with my router.

The last thing before installing them was to add the stud screws. The hand planing gave a really nice finish so I skipped the sanding.

My new Workshop

I have started building a workshop for my wooden projects in a small room that used to be a storage room and before that it was a horse stable.

The room is 17 square meters and I want to cram as much of my wood working tools as possible in here.

Heating will be provided by a wood boiler in an adjacent room.

So far have I only cleaned out stuff that does not fit here anymore and painted two walls.

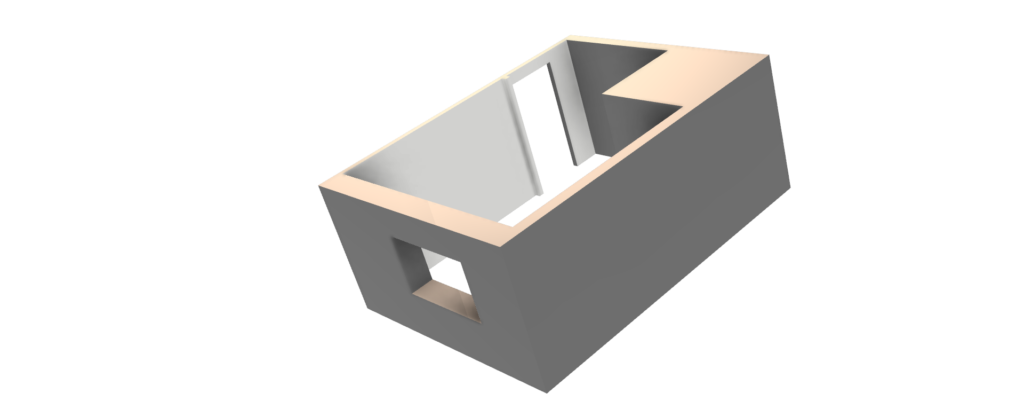

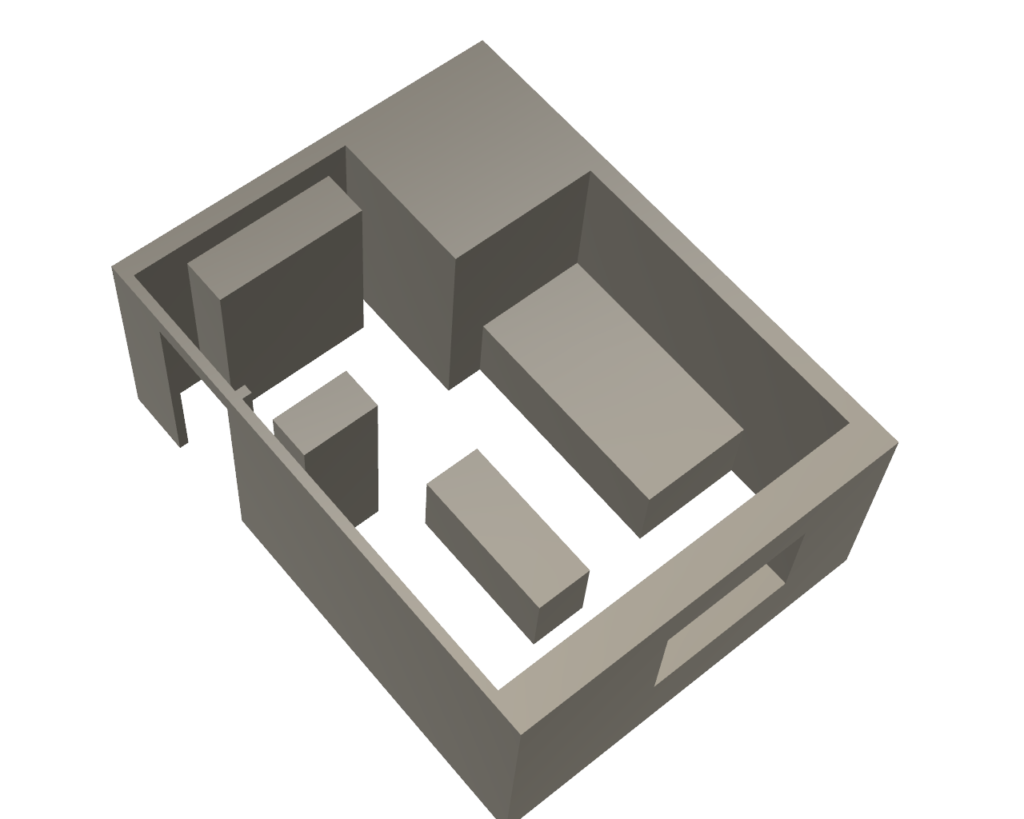

To get a feel for what to I can squeeze into the room have I created a 3D-model of the room.

Now I can visualize how the workbench and other things will fit inside the room.

MFT table

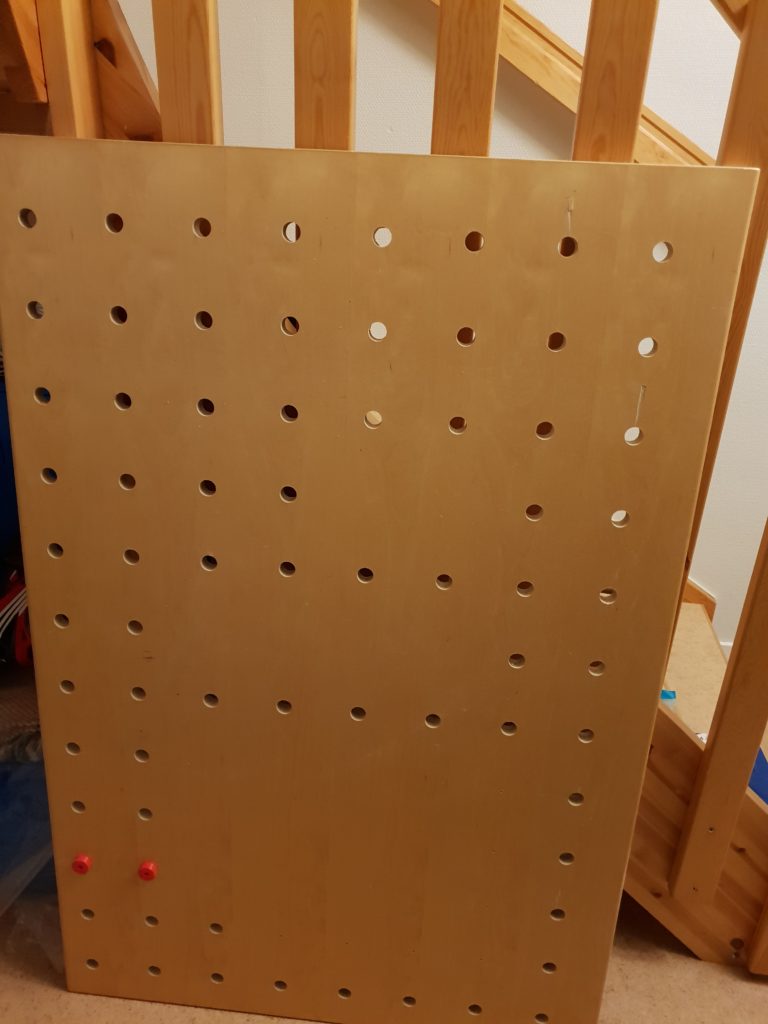

It actually started a while ago when I saw David Stantons series about his Stanton bench. I thought is was pretty cool and it seemed like a very good design. Fortunately I found out a friend of mine owns a UJK parfguide system and did let me borrow it. Thank you Pedher!

I started drilling my MFT table last week and today I finished the drilling process. The board is an old desktop that I got for free. It is made out of veneered particleboard.

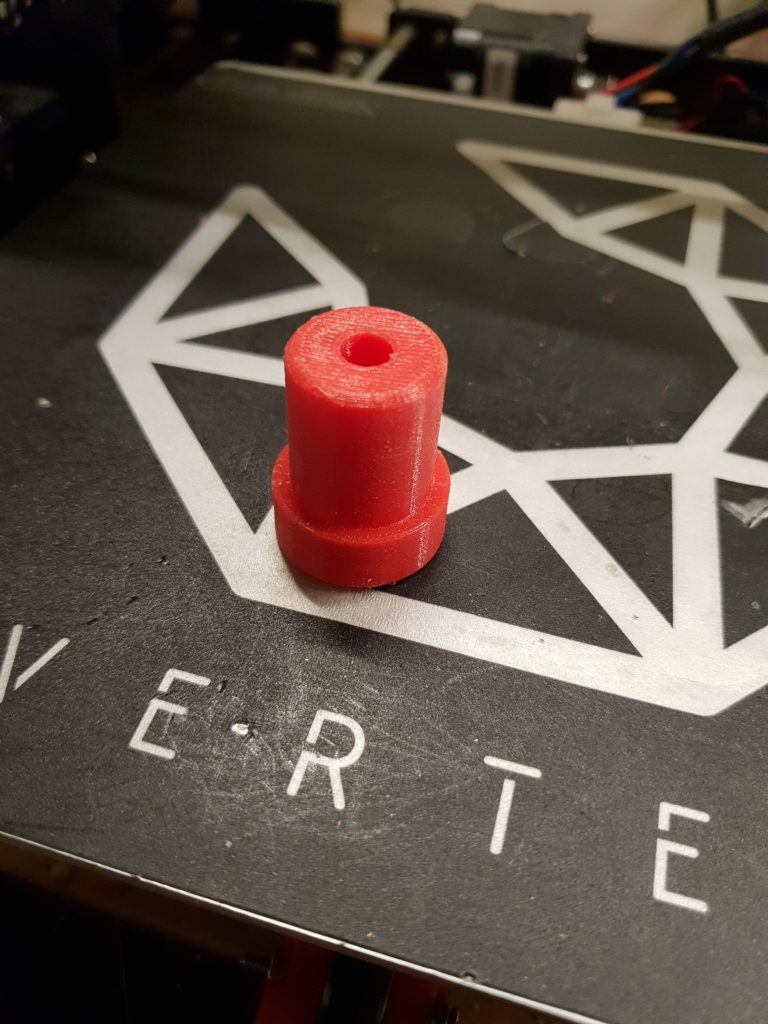

When drilling the table I realized that I needed some dogs for the table and sketched up a dog in Fusion 360 and printed it in PET-G. First one I made was 20mm in diameter and too tight in the newly made holes. I then made new ones that are 19.9 mm and they fit perfectly.